This time, let’s start with some quick practical case from the perspective of price,

CASE1:

If a purchaser is asking you to be competitive by 10% from his existing source, that means he is asking you to reduce the LOH by 80% at least.

–Is that even practically possible?> Yes, you have to give up your margin (Don’t you do that today?).

CASE2:

Factory Y is paying 3 times more average LABOR wage compared to Factory X. Yet, Factory Y is competitive by 2% in FOB.

–Is that even practically possible?> Yes. factory Y has to be efficient by +30% than factory X

(same as Bangladesh (X= 45% overall efficiency) and China (Y=75% overall efficiency) today).

“The price competitiveness is defined only on ≈15% of FOB.

Any factory barely have any control over rest ≈85%.”

Means, >85% of the price is already fixed (measurable and comparable with competition),

and only part to make a difference is 15% of the total; i. e, Labor and overhead cost (competitive advantage). Surprising? Well let’s have a look into the full story.

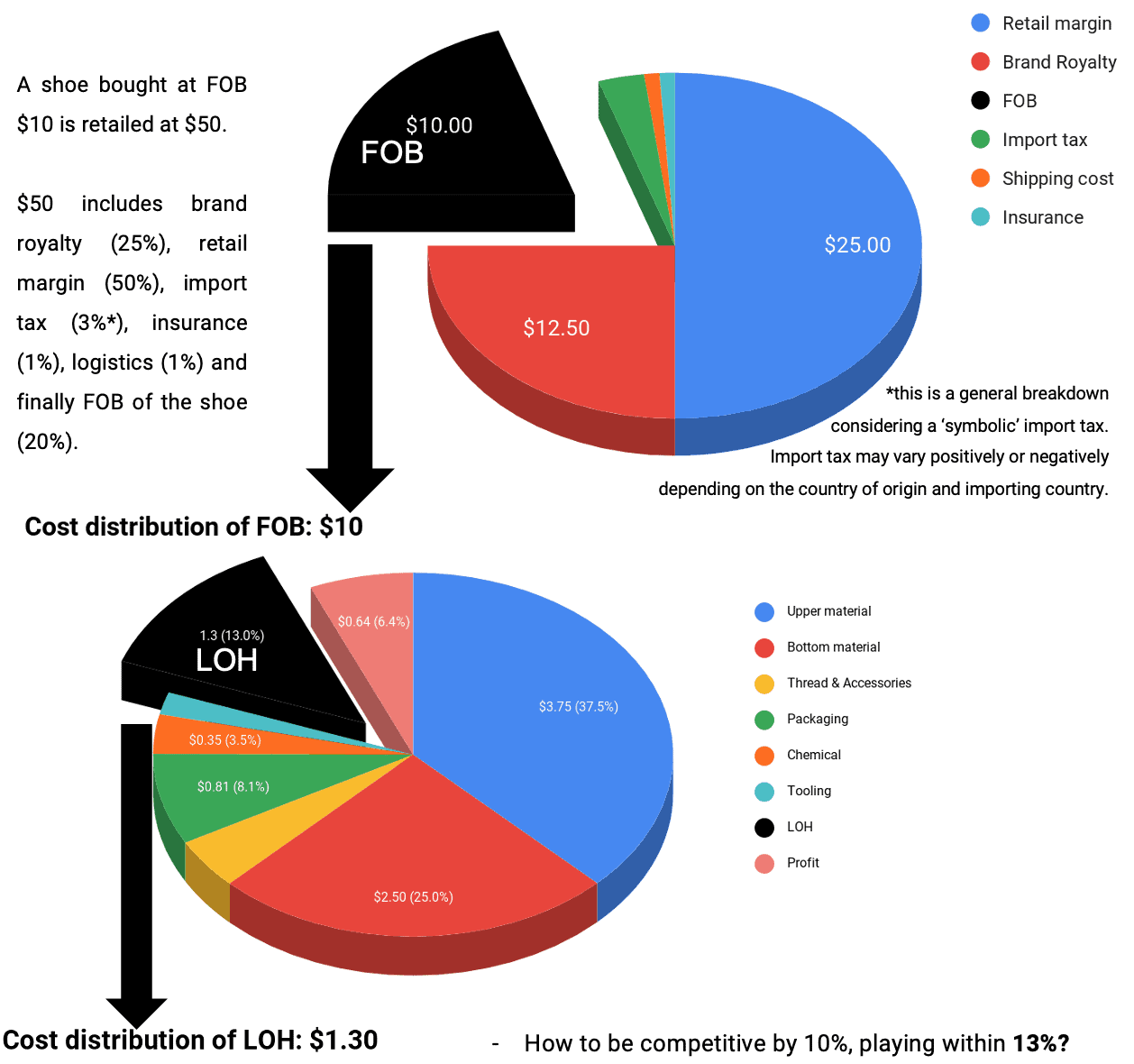

Retailers price breakdown: $50

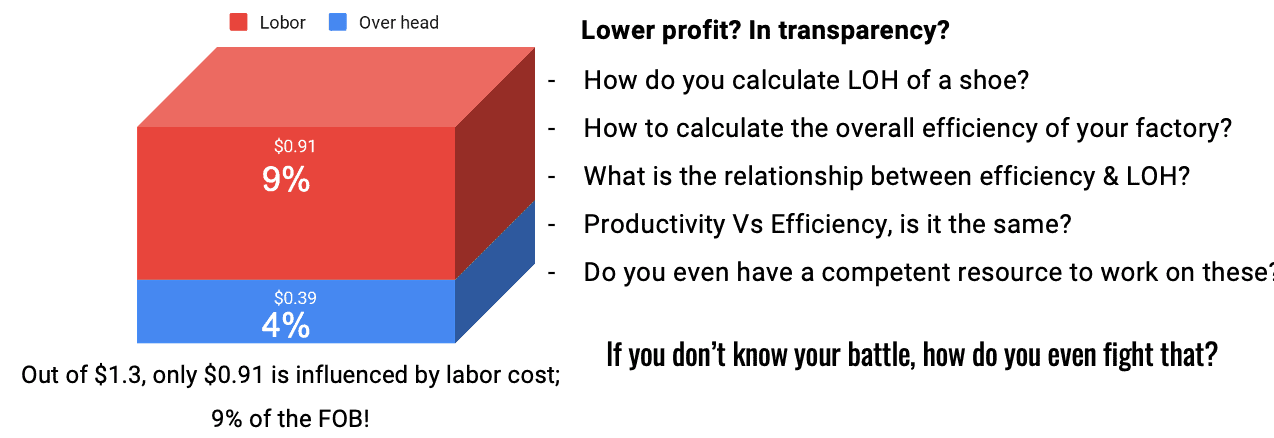

So, now let’s start with LOH; To calculate LOH, we need 3 information,

a. Cost of a minute in the factory

Total cost of the factory for a month (fixed + variable)/ number of working minutes in a month* = Cost of a minute

*timeline can be chosen as per the need (you can consider month or year or even a day)

EXAMPLE:

If there are 270 direct and 30 indirect worker (manager/ supervisor..) in the factory; the total working minutes of the factory is 270 direct workers X 25 working days in a month X 8 working hours every day X 60 minutes in a hour = 3,240,000 minute.

| Salary | = (3,000,000/3,240,000) | = 0.93 Taka/Minute | |

| Interest | = (1,200,000 /3,240,000) | = 0.37 Taka/Minute | |

| Depreciation | = (1,000,000/3,240,000) | = 0.31 Taka/Minute | |

| Rental Expense | = (700,000/3,240,000) | = 0.22 Taka/Minute | |

| Transportation | = (500,000/3,240,000) | = 0.15 Taka/Minute | |

| Repair & Maintenance | = (1,000,000/3,240,000) | = 0.31 Taka/Minute | |

| Utility Expense | = (800,000/3,240,000) | = 0.25 Taka/Minute | |

| Total cost of Minute | = 2.53 Taka/Minute | (a=$0.03) |

b. SAM of a model

Number of working minutes needed to produce a pair of shoe or, the time a single worker will take to make the pair.

EXAMPLE (I will use the simplified version to keep the ‘sense’ useful for all):

Measure the time of each operation by a stop watch,

operation A+ operation B+ operation C+ . . . . . .+ operation Z= SAM of a specific design (b= 25min)

c. Efficiency of the factory

The percentage ratio of ‘useful’ minutes to make the shoe and ‘used’ minutes.

EXAMPLE:

270 workers in a line (cut to pack) works for 8 hours a day produced 2,000 prs and SAM of the shoe is 25 minutes.

| Total minutes produced | = (2,000 x 25) | = 50,000 minutes | |

| Total minutes attended | = (270 operator x 8 hours x 60) | = 129,600 minutes | |

| Efficiency | = ((50,000 x100)/129,600)% | = 38.58% | (c = 38.58%) |

So, the LOH for this specific model in this Bangladeshi factory will be,

LOH= a X (b / c) =0.03 X (25 / 38.58%) = $1.944

I know this is boring, but it’s going to be interesting from here….

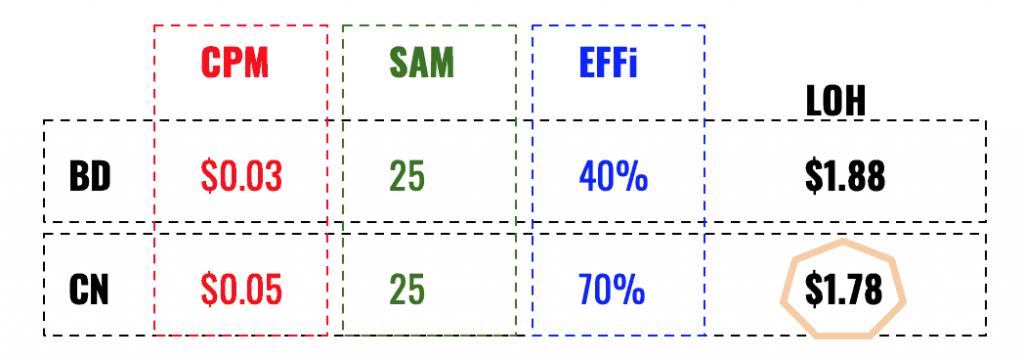

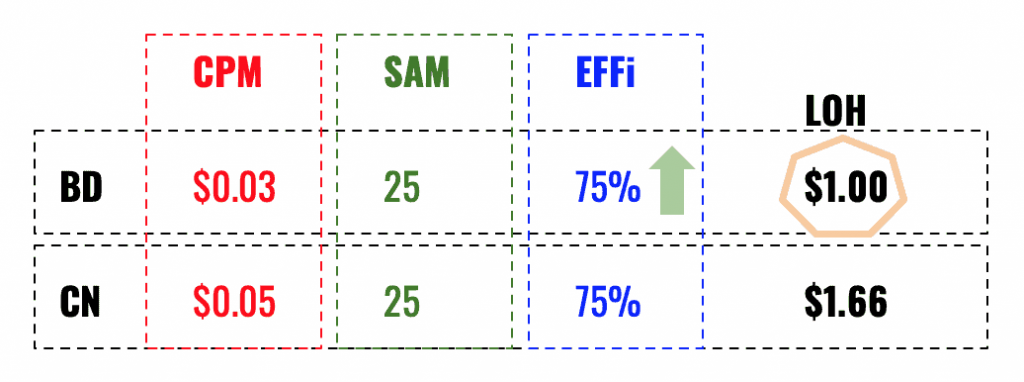

NOW, let’s do a comparative pricing between Bangladesh and China,(considering BOM, tooling cost and profit margin are same for both the countries)

Reality of today:

*CPM is based on country economy and labor market; factory has hardly any control over it.

**SAM is based on type of article/ design of the product; and it’s same for a product in all factories.

***EFFICIENCY, the only factor inside LOH that can be improved with right intention and investment.

“Today we are saved by the ‘kindness of God(s)’; GSP (generalized system of preference). A factor we don’t control. A factor depends on the geo-political polarization!”

This is my dream of tomorrow:

An improvement of 5% in efficiency will allow a factory to save more than 2% of FOB; 11% of LOH! A savings of $0.21 in each pair*! How difficult is it? Bad news is, we are bad at efficiency; and the good news is, we have an ocean to improve.“Efficiency is our ‘industrial God’ of future; our saviour for next decades”

References:

–https://solecollector.com/news/2014/12/how-much-it-costs-nike-to-make-a-100-shoe

–https://www.sneakerfactory.net/2019/05/cost-to-make-a-sneaker/

–https://ordnur.com/garments-2/calculate-garments-cost-of-making/

–https://www.onlineclothingstudy.com/2011/09/4-how-to-calculate-efficiency-of.html

–https://www.everycrsreport.com/reports/RL33663.html

https://www.idc-cdi.com/the-eu-needs-to-appreciate-cambodias-role-and-voice/

(This article is the part of Author’s upcoming e-book ‘Defining competitive advantage of Bangladesh for Footwear’)

Author

Hossain Tawhid Imam

A manufacturing industry passionate working as STRATEGIC INDUSTRIAL BUYER with the responsibility to build and deploy worldwide mid and long-term purchasing strategy for Footwear Industrial Division of DECATHLON.