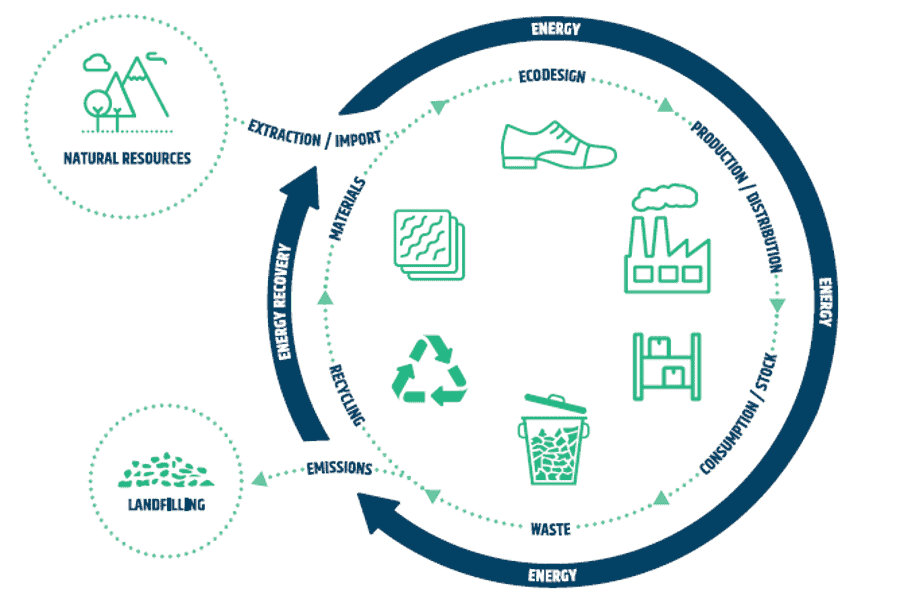

Climate change and sustainability are the topics of the day. The climate change is a real problem that affects the worldwide population and needs to be faced and urgent actions are needed in order to save the planet. The footwear industry is conscious and prone to integrate the aspects related with the environmental sustainability and circular economy in the development of new footwear concepts and production processes. Many companies have already started the journey to achieve a “sustainable growth”, “carbon economy” and “low carbon footprint” footwear products. The development of “truly” environmentally sustainable footwear products begins with the design process that should be based on Life Cycle Thinking. At this stage, it is fundamental to define the shoe concept and consider the entire footwear value chain, from the selection of raw materials to product’s end-of-life.

1. Design for function

- Product functional optimisation

- Multifunctional products that can be used in different applications

2. Design for durability and reparability

- Consider longevity, reparability and maintenance of the product

- Consider environmental improvements due to new technologies

- Easily repairable products, increasing the shelf life and reducing waste.

3. Design for recycling, reuse and recovery

- Reduce the material complexity

- Disassembly products to allowing the separation of the materials and components for recycling.

-

4. Select low impact material

- Select certified material with lower environmental impact

- Use natural, recycled, recyclable and biodegradable materials available on the market (e.g., cork, wood, recycled tires, recycled and recyclable polymers)

-

5. Reduce the use of materials

- Reduce the weight and volume

- Select as few different materials as possible for the same footwear, thus facilitating subsequent recycling.

-

6. Avoid potentially hazardous substances and materials

- Select materials in compliance with REACH legislation or other applicable legislation.

- Avoid materials that affect the ozone layer, such as VOC, fluorinated gases.

-

7. Optimize production techniques

- Processes that make the use of more efficient materials, for example, computer controlled cutting machines.

- Use materials that do not need additional treatments, for example, surface treatments to certain soles prior to bonding.

- Raise awareness among workers about energy consumption so that production processes are more efficient and about the advantages of reducing waste generated during production.

-

8 Select more environmental efficient distribution techniques

- Use containers of standard and modular size, to maximize transport.

- Transportation by train or marine container is preferable to the truck, they are less polluting. The use of electric vehicles will always be preferable.

-

9. Reduce the environmental impact in the use phase

- Avoid designing for passing trends. This causes it to be replaced once the design has become old. Ensuring that the aesthetic life is not shorter than the technical life.

- Spares parts (e.g., laces, insocks, fashion accessories) that can be replace in case of damage.

-

10 Optimize the end-of-life

- Provide information to consumer about the best alternatives at the product end-of-life (destination of post-consumer shoe).

- Promote and collaborate on the creation of a platform for waste management of footwear products at the end-of-life.

-

—————————————–

This can consider as literature summary of Eco design Guide for the Footwear Industry developed under the Life GreenShoes4All project